|

Tribology in industry

. . . . . . . . . . . . . . . . . . . . . . .

Development of Tribological Center

. . . . . . . . . . . . . . . . . . . . . . . |

|

TRIBOLOGY CENTER |

|

|

THE EQUIPMENT |

|

|

|

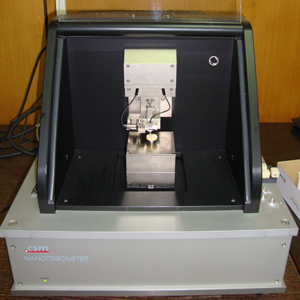

CSM Nano-tribometer

Nano-tribometer is designed for material researches – determining the friction force and the friction coefficient for given normal contact load and number of revolutions/number of cycles, according to ASTM G99 standard.

Contact geometry: Ball-on-Disk

Movement: reciprocating linear module and rotational module

Size of normal force: 50μN-1N

Radius ball: 1.5 and 2mm |

|

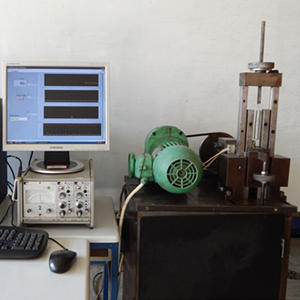

Tribometer TPD-95

Computer-supported Tribometer TR-95 is designed for tribological tests – determination of force and wear coefficient for proper contact conditions (normal load and sliding speed) according to ASTM G77 standard. The tests may be done in conditions with lubrication and without lubrication.

Contact geometry: Block on Disk

Normal force: 0-500 N

Sliding speed: 0.2-2.5 m/s

Block dimension: bb=6.35 mm lb=15.75 mm hb=10.16 mm

Disk dimension: Dd=35 mm and bd=6.35 mm |

|

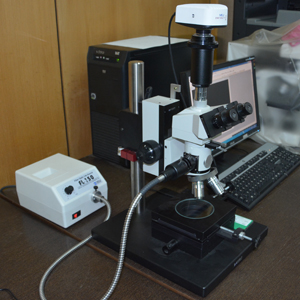

Microscope MC-50T

Meiji Techno's measuring microscope MC50 is designed for visual control and measuring small parts and components. Characteristics:

- precise moving of work desk in X, Y and Z direction

- magnification: 50X, 100X, 200X, 400X i 800X

- CCD color TV camera

- computer-supported |

|

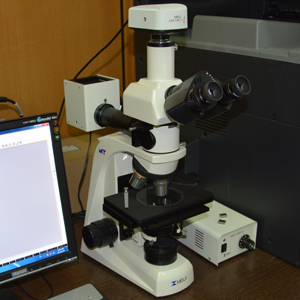

Microscope MT-8530

Meiji Techno's metallurgical microscope MT8500 with EPI BD optics that provides exceptionally bright and sharp image with good color contrast. Characteristics:

- precise moving of work desk in X, Y and Z direction (23mm pace)

- magnification: 50X, 100X, 200X, 400X, 500X i 1000X

- CCD color TV camera

- computer-supported |

|

Talysurf 6

Computerized measuring device Talysurf 6 (Taylor Hobson) provides complex defining of contact surfaces conditions. The device provides a wide range of possibilities, as following:

- measuring basic and additional parameters of roughness and waviness,

- statistic result processing of measuring roughness parameters,

- displaying results on the screen, their memorizing and printing,

- special scanning of surface.

|

|

Universal measuring microscope UIM-21

Universal measuring microscopeUIM-21 is designed for measuring lengths, angles, parameters of external and internal coils, tool control, objects of complex configuration, measuring wear traces. |

|

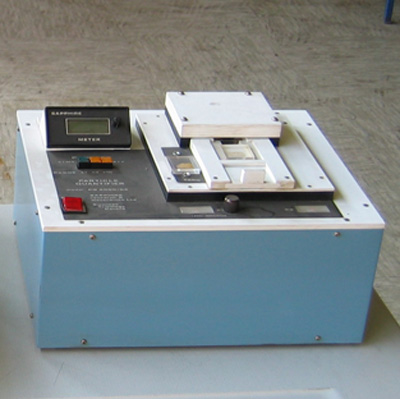

Particle quantifier PQ2000

PQ 2000 (Particle Quantifier 2000) device is designed to assess the number of metal particles in oil sample. Quick test takes about 10 seconds. Carbon materials do not affect the assessment of number of metal particles. Oil sample is exposed to magnetic field, the presence of metal particles causes’ violation of the field which is presented as PQ index. Range of particles detection is from 1 to 2000 μm. It is primarily designed for testing of hydraulic and lubrication oils. |

|

Rotary particle depositor

R.P.D. (Rotary Particle Depositor) provides simple and quick way of isolating wear products in oil by magnetic method and thus the samples are obtained that could be later on additionally tasted under microscope. RPD combines magnetic and centrifugal method of separating wear products. Rotary speed is 0-200 o/min. Wide range of particles size that could be isolated, is practically from 1 to 2000 μm. Time necessary for deposition and preparation of sample for analysis under microscope is about 6 min. It is suitable for testing of lubrication and hydraulic oils and lubricants. |

|

|

|

|

|